Pregius and Pregius S are Sony’s technological trademarks for a group of CMOS sensor global shutters and their peripheral technologies.

CMOS image sensors with Pregius and Pregius S technology are ideal for imaging inspections in machine vision and the smart industry that require the processing of a large volume of image data at high speed, as they make it possible to capture high-quality, undistorted images at high speeds.

These products also expand the scope of their applications from factory automation to other industrial imaging and sensing contexts, such as traffic monitoring and infrastructure inspection.

Global shutters function enables the capturing of fast-moving objects without distortion. Texts are legible in images

Our proprietary column A/D conversion circuit realizes both faster signal processing and lower noise. Enhancing the high-precision image inspection, it helps to improve on-site productivity in manufacturing

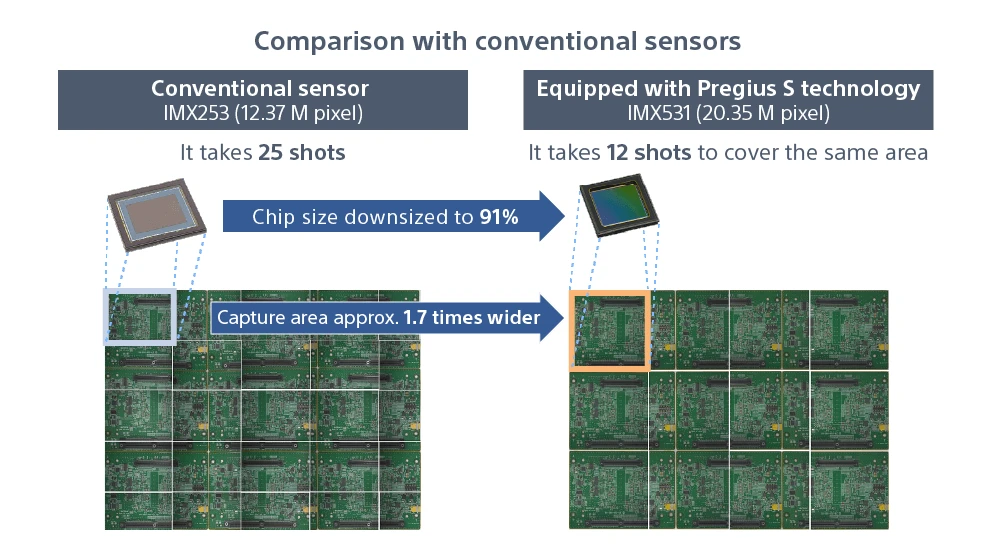

The back-illuminated pixel structure adopted in Pregius S global shutter technology has made both higher definition and smaller size a reality, on top of its non-distortion imaging functionality.This new structure has a superior light collection efficiency compared to the conventional front-illuminated structure and, while maintaining the levels of sensitivity and saturation capacity, achieved a reduction of the pixel size down to 2.74 µm square, about 63% of the conventional models.*1 In addition, rearranging the circuit area from the edges to the back of the sensor area has helped to achieve a 1.7-fold increase in resolution for the same optical size and reduce the package size to about 91% of the existing products.*1

As a result, it can achieve a high-definition small-sized machine vision camera compatible with up to approx. 24.45 M effective pixels in a C-mount 1.2-type sensor, allowing more flexibility in its applications to systems and production lines.

*1) Compared to "IMX253" and "IMX531," Sony’s 1.1-type CMOS image sensors with 12.37 M effective pixels.

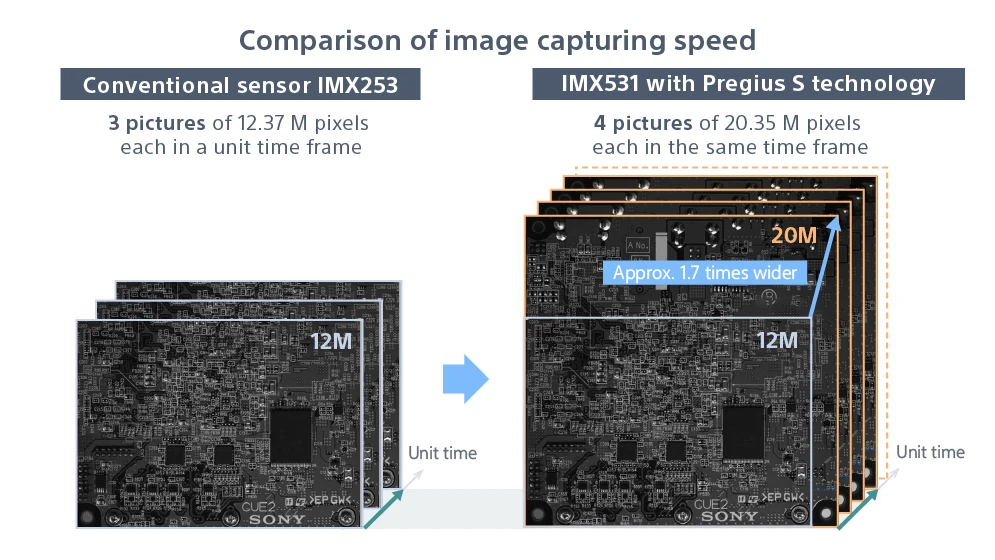

Data readout has significantly improved (2.4 times faster than previous products*1) in Pregius S by virtue of the highly-flexible wiring layout potential of the back-illuminated pixel structure, together with the adoption of SLVS-EC, a high-speed interface standard for adopting the embedded clock style. This potentially improves the takt time and throughput of the manufacturing systems or equipment.

As technologies such as USB 3.0 and 5 GigE become more prevalent, our standard 5 Gbps-compatible product range is enhanced by an extensive lineup of high-speed products for high-end cameras that use a high-speed band, improving the productivity significantly through reducing the time necessary for inspection, image recognition, identification, measurement, and other types of measurement and inspection.

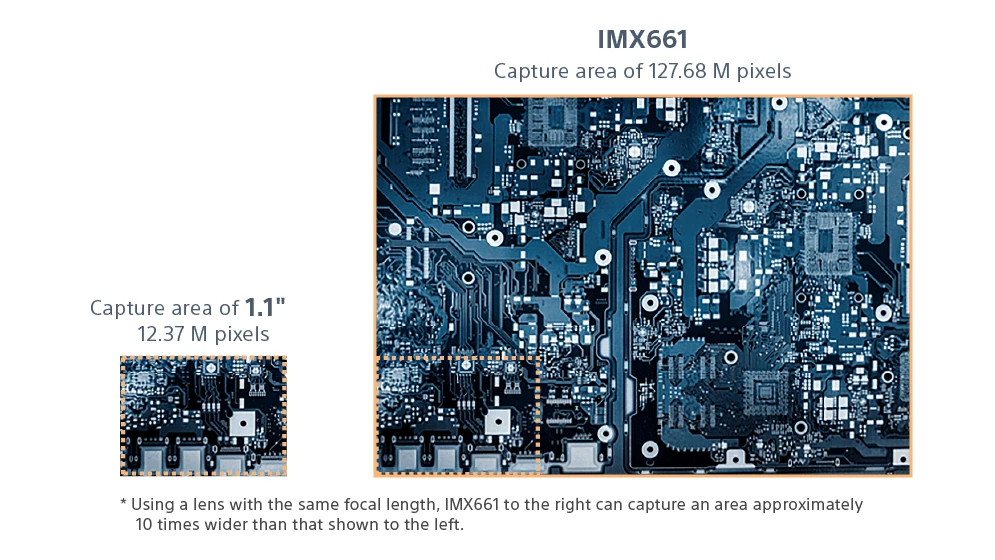

C-mount lens compatible image sensors are a standard option for industrial machines, but larger unit multi-pixel sensor will enable high-definition imaging of wider areas.

For example, a comparison between the images taken with 1.1” 12.37 M pixels sensor and one with 127.68 M pixels sensor clearly shows the difference. This will enable to lower capture frequency, which contributes to improved efficiency. It also enhances recognition accuracy by the high resolution imaging.

Comparison of capture area size

Sony offers two types of large CMOS image sensors for industrial applications: global shutter and rolling shutter. This video explains the differences and advantages of each.

Find out more about the global shutter technology

Part of this product group uses high-speed interface standard SLVS-EC